What Is the Difference Between Alloys and Ceramics? (Helpful Examples)

In modern times, alloys and ceramics are standard materials. Most households have appliances and utensils made from these materials. However, are these materials the same? How are they different?

A ceramic has different chemical properties from an alloy. Their unique characteristics, such as conductivity, strength, chemical resistance, and workability, make them unique. Moreover, they have a wide array of applications in the modern world.

I will describe the properties of these two materials, as well as their applications today. I will also explain the differences between the two.

What Is Alloy?

An alloy is a metallic material made by combining two or more elements. The constituents of alloys are ordinarily metals. However, carbon, which is a nonmetal, is a vital component of a majority of alloys.

To produce an alloy, you will have to melt the mixture of ingredients. Then pour the molten state of the elements into sand or metal molds and allow them to solidify. Melt the major components first, add the others later, and allow them to dissolve completely.

The biggest challenge in making alloys is the different melting points of metals. For example, copper melts at 1,984 degrees Fahrenheit, while zinc melts at 787.2 degrees Fahrenheit. This means that in making brass, zinc will be boiling and vaporizing by the time copper melts.

To avoid vaporizing metals with low melting and boiling points, it is best to first melt the metal with a high melting point (copper). Then add solid zinc, which will quickly dissolve into the liquid copper before much zinc boils and vaporizes away.

The process of making alloys is sometimes complicated. This is so especially when the metal with a higher melting point is needed in a smaller proportion. In such cases, the process is done in two stages.

But why go through this process just to make an alloy? I will discuss the properties of alloys in the following few paragraphs and make you understand the purpose of producing alloys.

The Purpose of Making Alloys

Most pure metals have few vital metallic and physical properties. These properties are enhanced and modified by alloying with other metals or nonmetals to fit the need. I will explain the importance of alloying:

- Alloying improves the hardness of a metal. This is because alloys are more rigid than their components. Pure metals are soft, and their hardness is improved by alloying them with other metal or nonmetal elements.

- Alloying lowers the melting point of pure metals. A lower melting point makes metals easily fusible. Alloying helps make solders which are valuable alloys.

- Adding alloys to pure metal increases its tensile strength. Alloys are therefore able to withstand enormous loads without fracturing.

- Resist corrosion. Unlike alloys, pure metals are prone to corrosion. Pure metals can easily rust since they are chemically reactive.

- Alloying modifies the color of pure metals. Add metals or nonmetals with suitable color pigments to alter the color of pure metals.

- Improved castability. A good casting requires expansion during solidification. A pure metal, however, contracts when solidified. Alloying metals improve castings because alloys will expand on solidification.

Is Ceramic an Alloy?

Ceramic is not an alloy. Instead, ceramic is an inorganic, nonmetallic material. Ceramics includes compounds such as carbides, nitrides, and oxides.

Ceramics are made from either nonmetal or metal compounds that are shaped and hardened by heating.

According to Dr. Ian Brown, the term ceramic has a more expansive meaning. Traditional ceramics are clay-based and have high performance. Advanced ceramics, on the other hand, are made from a variety of inorganic nonmetal materials.

Earthenware, stoneware, and porcelain are the three major types of traditional ceramics. I will briefly explain these three major types of conventional ceramics. I will also touch on advanced ceramics.

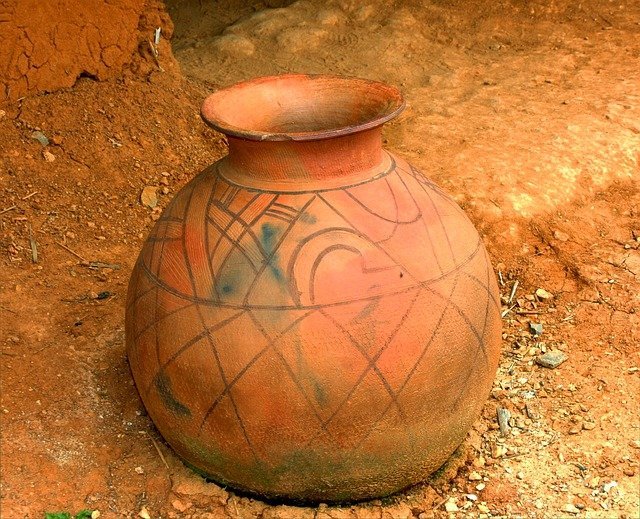

Earthenware has been used in pottery for many years. First, clay is fired at low temperatures to produce a porous, coarse product. The product is then covered with a fine glass powder and fired again, making it less absorbent.

In stoneware, clay is fired at very high temperatures until it is glass-like. As a result, stoneware is nonporous, chip-resistant, sturdy, and durable. Thus, stoneware is suitable for baking, cooking, serving dishes, and storing liquids.

Porcelain is a hard, translucent ceramic that originated in China. Small amounts of granite, feldspar, and glass are ground and mixed with kaolin clay. Then, add water, and the mixture is kneaded, shaped, and fired in a kiln.

Advanced ceramics are not clay-based but based on oxides, non-oxides, or a combination of both. Oxides used in making modern ceramics are alumina and zirconia. Non-oxides used are carbides, silicates, nitrides, and borides.

Advanced ceramics are well established in everyday use. These ceramics are used in various industries such as electronics, aerospace, automotive, personnel protection, and metal production.

Advanced ceramics are polished to a high finish and used as bone substitutes and dental implants in modern medicine.

What Is the Difference Between Metals and Ceramics

Though both ceramics and metals have similar uses, especially in households, these two materials are very different. To understand their differences, I will discuss the various properties that make them different.

- Electrical conductivity. Electrical conductivity refers to a material’s ability to carry electric current. Metals have high electrical conductivity, while ceramics are poor conductors of electricity. Ceramics are good insulators.

- Thermal conductivity. Thermal conductivity refers to a material’s ability to conduct heat. For example, metals are good heat conductors and will therefore transfer heat. On the other hand, ceramics are poor heat conductors.

- Corrosion. Corrosion is the process of destroying, damaging, or weakening slowly by chemical action. Corrosion is a problem for metals, while ceramics are corrosion-resistant.

- Workability. Metals are malleable and ductile, meaning that they can quickly be hammered into shape without breaking. On the other hand, ceramic is hard and breaks easily when subjected to stress.

- Tensile strength. Tensile strength is a material’s ability to withstand a pulling force. The tensile strength of metals is high and will therefore not break when subjected to tensile force. On the other hand, ceramics have low tensile strength and will break when subjected to force.

- Plasticity. Plasticity is the ability to be easily molded or shaped. For example, metals can easily be shaped or molded, while ceramic cannot.

The different properties between alloys and ceramics dictate their applications in life. Understanding these differences ensures that you use suitable material to make an item.