How to Glaze Cement Pottery? (Explained)

How to Glaze Cement Pottery – Clay is not the only material that is used for making sculptures.

Another popular option can be concrete, a material that can be poured into molds creating nice decorations for your garden plants. If you are bored with the original gray tones of concrete, you must be wondering if it is possible to glaze your work.

Normal concrete is not possible to glaze in a kiln. The reason is that at high temperatures, concrete would turn into sand and dust. Glazing is only possible with a specialized product called Densit. Other concrete pots can still be decorated with a couple of different methods.

To understand this process better we need to separate things made of cement from pottery. The object we made of cement is never called pottery, it is called concrete.

As pottery is made of fired clay, It gets hard when dried clay is taken to a high temperature.

So pottery kilns are very hot and temperatures can reach between 1900 F to 2300 F (1049 °C to 1300 °C) for high-fired pottery.

Concrete is made of cement and fine and coarse aggregate. The lime in cement is made by heating limestone in a kiln. To do this it is heated in a kiln to 1650 °F- 1800 °F (890 °C to 980 °C).

Related: All You Need to Know about Kiln Temperatures in Pottery

The chemical reaction that happens after we mix cement with water will make cement hard.

If we heat normal concrete at high temperatures it will begin to return to the original powdered state. Concrete was recognized as fireproof material because it does not burn and house fires are low temperatures that usually cannot do significant damage to concrete.

But if we heat a piece made of concrete very rapidly to pottery temperatures then pieces will fly off and explosive spalling of the concrete can result.

The water inside the concrete needs to evaporate slowly but if you put it in a very hot and very quick-firing, the water inside the concrete will boil.

That way the steam inside the concrete will generate expansive pressure and can initiate an explosion. This is something similar to what happens if you don’t dry enough a pottery piece and fire it when it is still wet.

Almost all pottery is fired in a kiln to 1060 C and at that temperature in a long pottery kiln firing the cement will turn all to powder and sand.

The big exception is the very special and highly engineered Densit concrete developed by Anja Margrethe Bache.

On this link, you can find more about her work.

Cement is usually used in construction but in modern art can be a really nice piece in your garden.

Can You Glaze Cement pottery?

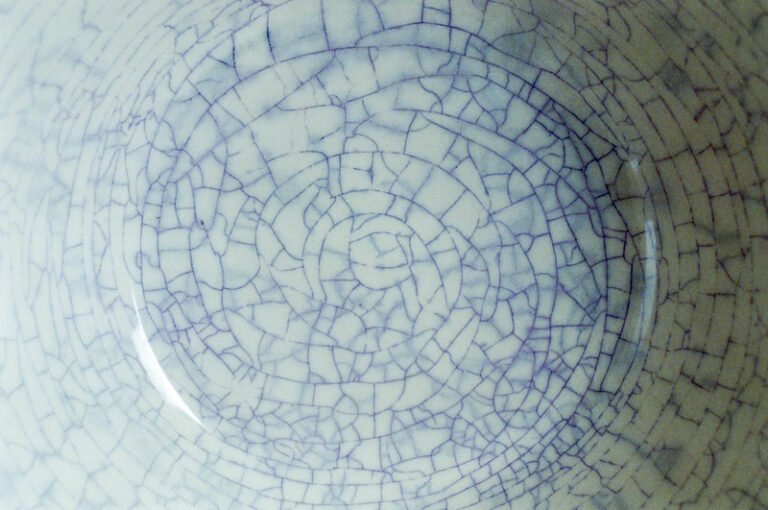

Glazing looks great on concrete plant pots, and it can be easily done in 3 different ways:

- Body dipping in the glaze

- Pouring the glaze on the pot

- Spray glazing

If you choose the last method then your concrete pot has to be heated to 100 °C to 200 °C in order to get a result.

Which Paint Is Best For Cement Pots?

Decorating your concrete pots is easy, but it needs to be done in the right way. If you want to use spray paint, make sure you look for a spray paint labeled for masonry.

This one is much better for sticking to the surface and more effectively adheres to concrete than any other standard spray paint.

Make sure that you paint your pots only when empty to avoid damaging the plant.

There is also special acrylic paint on the market that is called exterior paint which is resistant to outdoor weather conditions. It gives a nice finish touch to the concrete planter.

It can be applied to concrete, making it an ideal medium to use for an artistically updated concrete planter.

Can You Put Lacquer On Concrete?

Just like you can paint a concrete floor, you can do the same with your concrete pots.

Lacquering is an inexpensive way to refresh plant pots and decorate any piece of concrete that might look boring. It is not complicated, however, for the best result there are few rules to follow:

- remove any lumps by using sandpaper

- make the surface clean of dirt and debris

- make the clean surface by washing it with soapy water

- when it is dry, create unique patterns using a brush

Of course, make sure you wear protection for your eyes when working with sandpaper.

What Is The Smoothest Concrete Mix?

The most popular and most common type of cement is Portland cement, so that would be our recommendation. The typical ratio for this mixture of cement and sand is :

- 1 part cement

- 3 parts sand and water

How Do You Make Concrete Look Wet And Glossy?

You can always go a bit further with decorations on your concrete pots and make them more attractive. A glossy sealer creates a shiny surface and will give a wet-looking and glossy finish. Also, acrylic wax in the sealer is good protection against stains and water.