Can You Fire Pottery in a Fire Pit? All you need to know!

Many people love making pottery, but not all of them have access to a professional kiln. If you are an amateur potter, investing in a kiln may not be a smart decision. But are there any alternatives to a professional kiln? Can you fire pottery in a fire pit?

Of course, a specific setup is required, but you surely can fire pottery in a fire pit or use the campfire. When using a fire pit, controlling and adjusting temperatures is key. You will need to build a campfire in a specific way, so it has a glowing red heat.

In this article, I will discuss how to make beautiful ceramic items in a fire pit. You will learn about the kinds of clays that can be used for pit fires, and the temperatures you need to achieve to receive a satisfactory result when working with a fire pit. I will also briefly touch on firing and reglazing clay materials.

What Kind Of Clay Is Used For Pit Fires?

In simple words, pit-firing pottery is the most authentic method of baking clay. A pit is a hole in the ground, which retains temperature pretty effectively. Clay pots are placed and burned in a pit. However, while firing pottery in a fire pit, you should remember to use low-fire clay.

Low-fire Earthenware is the most suitable material for pit firing. This material is more porous and results in lower shrinkage. This material is non-vitreous, meaning that it absorbs more moisture and is very soft. For this reason, functional ware is almost always glazed.

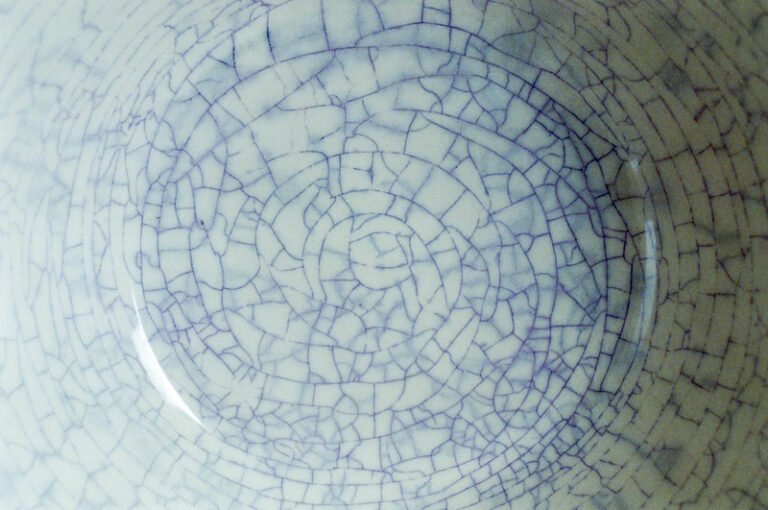

I think that there is another important characteristic of low-fire earthenware I should discuss. Due to its nature and consistency, this material may not be able to endure extremely hot temperatures. Frequent exposure to extremely high temperatures may cause Earthenware to crack.

If you are having your first stamps in pottery, then you will find earthenware clay extremely easy to work with. Advanced potters also love to work with this material for its unique features.

High-Fire White Stoneware Clay is another material perfectly suitable for pit fire. This type of clay has a small amount of sand. This feature increases its workability and strength, which causes them to slightly open while being pit-fired.

Raku is also frequently used for pit-firing. This material contains a smaller amount of grog; therefore, it is more suitable for handshaking than getting thrown on the wheel. Raku is quite porous, making it more suitable for low-fire temperatures.

Porcelain is another good material to bake in a fire pit. The characteristics associated with porcelain clay include toughness, a considerable degree of hardness and strength, and serious resistance to thermal shock & chemical attack.

What are Low Fire Clays?

As I have mentioned above, low-fire clays are the most widely-used types of clay for a fire pit. Low-fire materials are defined by the level of temperature at which the clay matures. For low-fire clays, this temperature is generally between cones 09 and 02 (1700 and 2000 degrees F or 927 and 1093 degrees C). Low-fire clays are very easy to work with and usually will not shrink. However, they are less durable.

There are two main categories of low-fire clays according to the color they receive after firing. The first category unites darker-colored clays, mostly red. Darker earthenware clay bodies may range from slightly orange-red to a dark brown. The second category united white clay bodies.

Low-fire clays are very popular among potters. Due to increased interest in those materials, new variants of low-fire clays have recently been developed. These clay types have also been given the label “earthenware” due to the fact that they mature in the earthenware temperature range.

Low-fire whistle clays were created in Europe when multiple factories began attempting to duplicate the porcelain ware. The white clays of today are still composed of about half clay and half added fluxing agents, such as talc.

Can you Refire Clay?

Glazed ceramic items are regularly refired (sometimes several times) as common practice for art pieces, and in some cases for domestic ware as well. Although this is not necessary for all materials and pieces, most pottery glazes need to be applied in 1-3 layers.

Ceramic items that have already been fired with a glaze can be re-glazed and fired one or two times. After the 3rd or 4th repetition, pottery starts to become unstable and weak.

Refiring can be a serious problem with the body and the glaze itself. Vitreous materials, especially when fired beyond their point of maximum density, can blister or even crack.

An important rule to take into consideration is that you should not re-fire at a hotter temperature than a previous firing. If you don’t follow the rule, it will burn off the lower temperature glaze.

For example, the first glaze can be fired at cone 6 (~2200F/1200C). You can do a second firing at the same temperature. You should do the third firing at Cone 04 and the fourth one even at lower temperatures.

The refiring process gets more complicated with other types of clays, such as Raku. You can’t refire Raku items in an oxidation fire, such as electric kilns.